In synthetic biology, microbes are often used to produce proteins based on natural models. Until now, however, its use has been limited to small proteins. The researchers have now succeeded in overcoming this hurdle and producing the very large muscle protein titin. The spun fibers of this molecule result in a material that is particularly resilient and stable, resistant to tearing, and can also be sustainably produced and biodegradable.

Some of the most exceptional, high-performance materials can be found in nature – from ultra-durable cobwebs to underwater shell silk to super-rubber resin, found in the ankle bones of fleas, for example. Previous attempts to technically replicate such materials have not approached the original materials and lagged behind the natural models in terms of environmental friendliness: “Industrially produced high-performance polymers are typically non-biodegradable and are obtained from crude oil through energy-intensive processes with toxic solvents and by-products”, A research team led by Christopher Bowen of Washington University in St. Louis writes.

Microbes as protein producers

Instead, Bowen and his colleagues took a different approach to producing a new, high-performance material: They found a way for genetically modified microbes to produce very large proteins that are identical to the original. “Many small molecules are already being produced sustainably using microbes,” the researchers wrote. “The direct microbial synthesis of high-performance polymers, on the other hand, is a major challenge.”

This is because most of nature’s super substances are made up of very large proteins. “However, it is very difficult to produce these in microbes because the efficiency of such large molecules is low and appropriately modified microbes are genetically unstable,” the researchers explained. To get around this problem, they decided on a trick. They just provided the microbes with tiny bits of large total protein and added places where the bits could be grouped together. In this way they succeeded in producing the muscle protein titin – the largest known human protein.

Fantastic flexibility

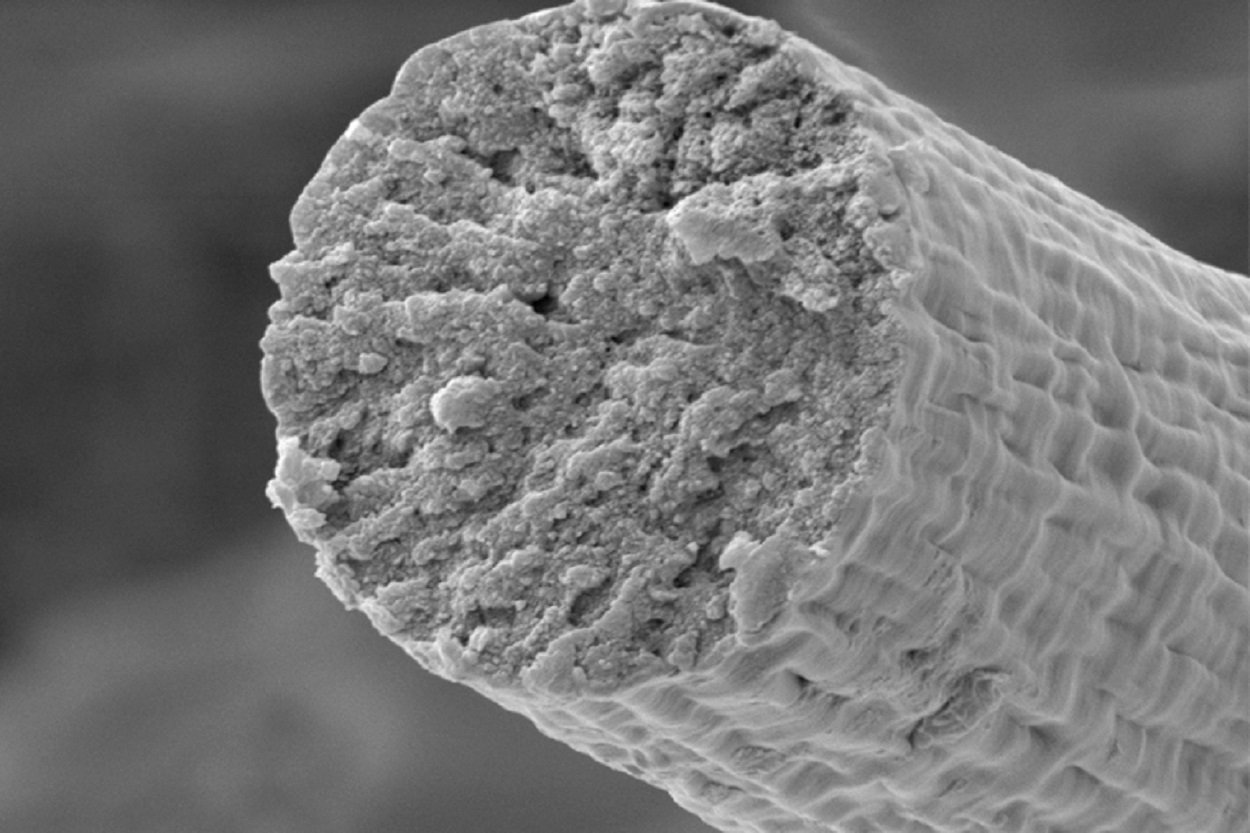

“In muscle tissue, titin gives muscles a combination of strength, cushioning ability, and rapid mechanical recovery,” the researchers explain. In order to achieve similar properties with microbially produced titin, they extend proteins into fibres. To do this, they first destroyed the 3D structure of the proteins with a denaturing solution. The proteins detected in this way were pressed into water through a fine-mesh needle so that individual titin molecules would bind to form fibers as they refolded. “Indeed, uniform cylindrical fibers formed,” the researchers say.

These fibers are ten micrometers in diameter, which are ten times thinner than a human hair. According to the researchers, about 250 meters of titin fibers can be obtained from a one-liter microbial culture. Next, the researchers tested whether the microbial fibers actually possessed the desired properties of natural muscle fibres. The result: “Both the strength and elasticity of these fibers far exceed the measured values of individual myofibers and myofibrils,” the researchers said. “In addition, these elasticity values exceed those of many of the toughest synthetic and natural materials.” Microbially produced titin is more stable than Kevlar.

Diverse application possibilities

Molecular analyzes confirmed that this exceptional flexibility is in fact due to the structure of particularly large proteins. “This underscores the value of the new strategy for making large polymers,” Bowen and colleagues write. According to the researchers, the new technology could also be used to produce other large proteins. “The nice thing about this system is that it really is a platform that can be used anywhere,” says Bowen colleague Cameron Sargent. “We can take proteins from different natural contexts, then put them in this polymerization platform and make bigger and longer proteins for different material applications with greater sustainability.”

From the researchers’ perspective, synthetic titin has many potential applications. Similar to Kevlar, it can be used for bulletproof vests, for example, but also for biomedical purposes. Since they are nearly identical to the proteins found in muscle tissue, it is likely that they are biocompatible and therefore can be used in sutures, for example.

Coyle: Christopher Bowen (Washington University in St. Louis, USA) et al, Nature Signals, doi: 10.1038/s41467-021-25360-6

“Alcohol buff. Troublemaker. Introvert. Student. Social media lover. Web ninja. Bacon fan. Reader.”

More Stories

“Time seems to cure long Covid.”

Science: The use of artificial intelligence is changing the way hospitals operate

Simple recipe: sweet cream cheese slices from the tray