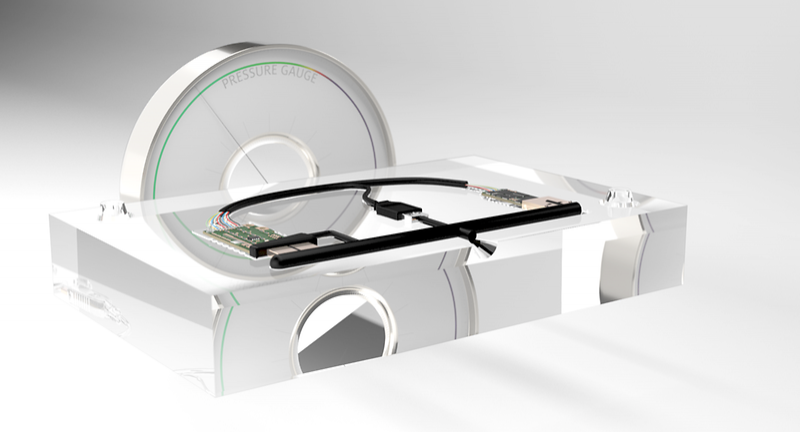

Henkel’s Low Pressure Molding (LPM) process, which is mainly based on polyamide hot melt adhesives, is increasingly being used to protect electronic components in the fields of medical technology, power generation, industrial automation, heating, ventilation and air conditioning technology, as well as as lighting technology. Compared with the traditional methods used, the technology should offer many process-controlled economic, structural and environmental advantages, such as encapsulation of electronic components with two-component casting resins or high pressure injection molding.

LPM was invented by Henkel over 30 years ago, then under the name “Macromelt Molding”. This allows sensitive components to be over-melted using polyamide-based hot melt adhesives in combination with appropriate curing systems and injection molding tools. Since Technomelt products are not abrasive and, compared to traditional injection molding, are injected with significantly lower pressure, the risks of damaging sensitive components during the LPM process are reduced.

Therefore this technology is particularly suitable for protecting sensitive components such as circuit boards or jumper cable connections. Technomelt’s hot melt adhesives are both strong and flexible, making them suitable for this type of application.

“For me, Technomelt hot melt adhesives are an exciting part of our portfolio in circuit board protection,” says Matthew Hayward, global lead account at Henkel for Power & Industrial Automation. “It has many unique advantages that conventional paint or pot processes cannot do. The ability to apply this material only where it is really needed is a huge advantage. This makes it possible to ‘plan’ an application (only to protect sensitive components) and significantly reduce weight. substantially using significantly less material.”

The material provides a high level of electrical insulation and is also resistant to a wide range of chemicals, temperature cycles, and vibrations. The components are thus protected from external influences such as penetration of water or dust as well as exposure to long-range UV rays. “Unlike conventional two-component casting resins, the polyamides used in the LPM process are thermoplastics,” explains Michael Otto, lead account manager in the engineering adhesives division of Henkel’s low-pressure injection molding processes. “Cycle times are much shorter and no volatile components are released. Whereas in a conventional casting process, it can take several hours to days to fully cure, with Technomelt’s low pressure molding process, a cycle time of a few seconds is achieved.”

Henkel’s Technomelt hot melt adhesives comply with the European RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations. “Another important environmental aspect of these polyamides, which is becoming increasingly important, is the fact that they are largely biologically based, meaning that up to 80 percent of their ingredients come from renewable plant sources,” adds Michael Otto.

Henkel offers a selection of Technomelt products for the LPM process, the formulation of which has been developed for specific applications. Some have particularly good heat resistance, while others have increased durability or adhere particularly well to certain substrates.

One advantage of the LPM process over conventional pot systems is greater economic efficiency in terms of material consumption. With traditional potting operations, the ingredient to be protected is usually placed in a container and filled until all ingredients are covered. In the Technomelt LPM process, the component is placed into a precisely defined tool and then filled with Technomelt. As a result, the components are protected with the least amount of mass possible. This means that you follow the circuit board structure, for example. It is also possible here to use multi-cavity tools in order to increase the pressure of several components at the same time.

Molds are usually made of aluminum, which is why production is cheaper than tool steel for “classic” plastic injection molding. In recent years, more efficient methods have been developed from the additive manufacturing field for the production of molds (3D printing).

The Internet of Things (IoT) and Industrial Internet of Things (IIoT) rely on sensors, connections, and necessary electronic components that connect all kinds of devices in the home, office, and on the go. This trend, in turn, has increased the demand for network connectivity for data and power cables as well as for connections, which must also operate in extremely harsh environments. In medical care, patient diagnosis and real-time measurements require new electronic devices such as wearables that can operate inside and outside of medical facilities. Therefore, the Technomelt LPM process aims to provide an answer to all of these trends.

For some medical applications, Technomelt can also be used in areas beyond the protection of electronic components. So it is suitable eg b. For connecting flexible hoses to fluid supply, as they do not twist the hoses and provide a permanently tight connection. For this purpose, Henkel developed Loctite PA 6951. The product was tested according to Henkel’s guidelines, which are based on ISO 10993, the series of biocompatibility standards. Certificates can be viewed upon request. More Technomelt products are planned to be qualified here.

Working with partners that manufacture process systems around the world, Henkel offers a comprehensive Technomelt LPM process solution: “These partners are extremely important to our success,” says Michael Otto. “Technomelt Low Pressure Molding is a comprehensive system in which materials, machinery, molds, and technical services as well as engineering are assembled. Our partners have their own sales force, supporting our access to global markets. In addition, Michael Otto emphasizes: “There are many other developments that increase the requirements for high-quality, cost-effective protection of components. At Henkel, we are convinced that Technomelt’s low pressure molding technology makes an important contribution to meeting these requirements.”

“Alcohol buff. Troublemaker. Introvert. Student. Social media lover. Web ninja. Bacon fan. Reader.”

More Stories

Ecologists Celebrate New Xesap National Park in Laos | Science

Is the wrong diet making you forget?

We can study it with a new telescope.